موقعك الحالي:صفحة رئيسية>المنتجات

2020.2.3 There are mainly two types of crushers available for this purpose- compression type or impact type crushers. There are many

Read More

2020.4.7 BASIC CEMENT PLANT LAYOUT 2020-04-07 16:40:31 Share to: PDF Download 1. Limestone Quarry and Crushing Plant The major raw material for cement

Read More

2020.7.24 This paper takes the specific characteristics of pulverized coal room in thermal power plant as the starting point,firstly, this paper analyzes the process layout

Read More

2020.7.24 Article history Received: 3 July 2020 Accepted: 3 July 2020 Published Online: 30 July 2020 This paper takes the specific characteristics of pulverized coal room

Read More

2023.1.1 The utilization of coal in the cement and concrete industries takes three basic forms: (1) as a fuel in the production of cement clinker; (2) ash produced by

Read More

2020.10.26 The heat source to run the very hot kilns can be either coal, natural gas, and/or biofuels. Coal is still used in approximately 90% of cement plants globally to

Read More

2023.5.12 crusher foundations. • With spring support, the crusher and its deck are usually supported on just two beams framed into the nearest building column. Only the

Read More

2023.10.14 Design of Coal Crusher House In the structural design of coal crusher house, it is not difficult to find that the vibration isolation and reduction design of coal

Read More

2018.12.26 There are two types of impact: gravity impact and dynamic impact. Coal dropped onto a hard ... Efficiency of a multiple stage crushing plant can be maximized by

Read More

Design And Lay Out Coal Stockpile And Crushing Plantlay out of coal crusher of cement plant; the explanation of mill operations will be based on this mill type. Figure 13.2 illustrates the typical key components of a VSM.Coal Ball Mill Layout. Coal Ball Mill Layout Pulverizer Wikipedia The ball and tube mills are lowspeed machines that grind ...

Read More

Cement Manufacturing Equipment. Cement Crusher. Crusher is a kind of machinery that is widely used in the cement production industry. It is mainly used in the material preparation process to crush the raw materials into

Read More

You cannot select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Read More

Cement Plant Coal Mill Grinding Flow She أكمل القراءة Hammer Crusher Working Principle - AGICO Cement Plant أكمل القراءة al pulverization in cement plant design أكمل القراءة lay out of coal crusher of cement plant ...

Read More

2024.2.11 Impact Crusher. An impact crusher uses impact force to crush materials. This crusher of cement operates by picking up the raw materials and throwing them against a hard surface or impact plate, causing them to break into smaller pieces. Impact crushers are often used for crushing softer materials, such as limestone, gypsum, and clay.

Read More

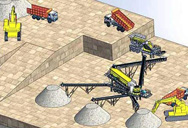

2016.2.24 can all affect crusher plant design. Construction costs are generally much greater at high altitudes, in cold climates and at remote sites. To improve the economics of such locations, modular and pre-assembled structures and plant facilities are used prior to transportation to site. Local labor costs often dictate what material

Read More

Hammer Crusher Impact Crusher. These two crushers are based on the impact principle of material crushing, with coarse crushing, medium crushing and fine crushing three types. Their main difference mainly lies in the broken part. The former uses the hammerhead hinged on the rotor, while the latter uses the blow bar embedded on the rotor.

Read More

Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line.Before sending it into the raw mill, the cement raw material should be crushed into small sizes by the cement crusher.. The cement raw material can be crushed by many methods including pressing shearing, rolling or

Read More

Mobile crusher, also called mobile crushing plant, mobile crusher plant.It is an advanced crushing equipment that is developed by many experts, and its outstanding advantage is convenient move, small area occupied, also no need of the operating place, directly applied to the cement production line, because the mobile crushing plant can be built directly on

Read More

2022.3.15 The cement clinker coming out from the kiln is then cooled and pulverized (> 90 µm in size) to ... Gyratory Crusher Jaw Crusher Cement Kiln The kiln is the heart of the cement processing operation. It is heavy, expensive and a piece ... Those cement plants which use coal/lignite as fuel need to have fairly large coal storage

Read More

The roller crushers are used for moist and sticky materials. Generally the machines have to be rigid enough to crush also hard inclusions. As the reduction ratio is only about 5:1 a 2-stage crushing is required in most applications. Fast running type crushers like hammer and impact crushers are the simplest and cheapest solution, whenever the ...

Read More

2019.10.30 The cement crushing process. The raw material can be broken by extrusion, shearing, rolling or impacting. The crusher works by a single or a group of them. There are jaw crusher, gyratory crusher and cone crusher which work by extrusion principle. Hammer crusher and impact crusher working on impact principle.

Read More

Lay Out Of Coal Crusher Of Cement Plant. Lay Out Of Crushing Plant 300 Ton Jam cafe . lay out mining plant 300 ton jam fsimworldorg coal crusher 60 ton h Solutions Infinity 60 300 T H Concrete Batched Plant Cap60 120 M3 H, Stone Crusher 60 steam coal Jual Stone Crusher Plant merk CGM kapasias 40 ton jam, 60 harga 100 Strip Mine Coal

Read More

2020.10.15 We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a transmission device, rotor, lining

Read More

2019.11.21 For meeting different requirements, we also provide single cement plant equipment, including cement crusher, cement ball mill, vertical cement mill, cement roller press, cement rotary kiln, cement dryer, clinker cooler, cement silo, etc. There is no doubt that each cement production line needs individual cement plant equipment, but, 3 cement ...

Read More

2019.9.27 There are various types of cement crusher on the market, including jaw crusher, cone crusher, hammer crusher, impact crusher, and etc. AGICO Cement can provide all types of cement crusher. Our cement crusher can fully crush the raw material, reduce feed size into the mill, and increase the reaction of raw material in the following

Read More

The structure design of a hammer crusher. We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce its structure and parts. This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a

Read More

The cement plant crusher unit is an essential piece of equipment in the cement manufacturing process. Its primary function is to crush limestone and other materials into small pieces that can be further processed into cement. One of the major benefits of the cement plant crusher unit is its ability to increase production efficiency.

Read More

A well-designed plant layout balances the capital versus operating cost over mine life. Buildings, infrastructure, and major equipment items, represent the major cost elements of a crushing plant. Yeco Machinery’s engineers will prepare a layout that suits the design criteria, flowsheet and selected equipment in the most economical possible ...

Read More

lay out 50 thp crusher plant, lay out 50 thp crusher plant ... grinding machine, coal crusher, ... 0 5 mn tonne grinding capacity is how much cement capacity, ... Go to Product Center. layout crushing plant for coal, ... coal crusher layout. Cement Mill Plant layout process crusher crusher Plant layout is the previous conditions of mining ...

Read More

Coal Crusher Lay Out Design 2022-04-25T06:04:50+00:00 Crushing Plant Design and Layout Considerations. Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a

Read More

Cement plant dwg. Cement plant. Viewer. Stiven riveros galindo. General plan of the cement manufacturing process. it is a vertical grinding system. Library. Machinery - mechanical. Machinery - industrial. Download dwg

Read More

2016.3.10 Crushing Plant Flowsheet Design-Layout. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less. Before the advent of the Symons cone

Read More

2022.2.22 Attention: If the feeding size is smaller than 115mm, 150mm, 200mm, it can be crushed by the spring cone crusher directly, and avoid the primary stage crushing. Second Method: 1. Technological Process: Coal ----- transported by the dump truck ----- Vibrating feeder ----- Roller crusher----- Circular vibrating screen ----- finished product as

Read More

Layout Of Cement Industry Crusher Grinding Mills Dwg Cement Plant Layout 3f Grinding Mill China

Read More

01 March 2016. Coal provides around 90% of the energy consumed by cement plants around the world, despite the environmental harm caused by its combustion. It takes 200 - 450kg of coal to produce 1t of cement. The cement industry consumes around 4% of global coal production, around 330Mt/yr. Given the rapidly-expanding infrastructure projects ...

Read More

You've already forked mill 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Read More

lay out of coal crusher of cement plant. Jun 27, 2013 hi this is abhishek sehgal from prakash industries from west bengal. kolkata. we expertise in setting up a cement plant .rotary kiln, vertical shaft kiln, white metal ball mill, tyre roller ball mill we are in this business from 30 years and have completed setting up 80 and more units of cement unit in eastern india

Read More

You've already forked crusher 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long. 1 Commit. 1 Branch. 0 Tags. 57 MiB . Tag: Branch: Tree: master. Branches Tags ...

Read More

coal crusher layout manharinCrusher Plant Layout Crushing Plant Layout Mining. lay out of coal crusher of cement plant Apr 3 cement manufacturing coal processing cement mill layout diagram of belt coal crusher machine Crusher Plant layout is the previous conditions of mining process Crushing Plant layout is widy used to limestone clay sandstone clinker

Read More

الصين -تشنغ تشو -المنطقة الوطنية للتنمية الصناعية للتكنولوجيا المتطورة، جادة العلوم رقم 169.

الصين -تشنغ تشو -المنطقة الوطنية للتنمية الصناعية للتكنولوجيا المتطورة، جادة العلوم رقم 169.